Nov 21,2025 / CABINETS

Best Countertop Materials for High-Traffic Kitchens

Granite kitchen surfaces display a diverse array of mineral compositions, which influence both their strength and resistance to wear and heat. Black granite countertops often contain elevated levels of magnetite, enhancing their durability against scratches and discoloration commonly found in high-use environments.

Gray granite varieties typically incorporate quartz and feldspar, affecting their color patterns and contributing to long-term structural stability.

Plywood cabinets paired with these countertops rely heavily on ply thickness and adhesive types to withstand moisture exposure, a frequent concern in humid cooking spaces.

Alternatives such as butcher block surfaces offer a warm aesthetic while providing functional resilience, and laminate counters present a cost-effective option that balances affordability with reasonable endurance and style.

Quartz Countertops Benefits And Durability

Composed primarily of 90-95% natural quartz crystals, these surfaces stand out for their exceptional strength and endurance. The engineered combination with polymer resins creates a non-porous finish, enhancing resistance to stains more effectively than many solid surface materials.

Quartz rates higher than numerous granite varieties on the Mohs hardness scale, decreasing the chance of scratches in highly used areas.

Despite offering moderate resistance to heat, these durable kitchen tops require caution with hot cookware, differing from more heat-resistant surfaces like soapstone surfaces.

Some producers incorporate recycled materials, promoting sustainability without sacrificing longevity or performance. Such attributes complement the qualities sought after following the evaluation of best countertop materials for high traffic kitchens with granite and plywood cabinets, preparing the way for exploring butcher block surfaces in hightraffic kitchens.

Butcher Block Surfaces In HighTraffic Kitchens

Hardwoods such as maple and oak demonstrate remarkable resilience, making them ideal for surfaces subject to frequent use and knife contact. Kitchen island surfaces crafted from these materials can absorb impacts more effectively than synthetic options, helping to maintain blade sharpness over time.

Maintenance-free counters remain rare within this category, as periodic oiling is necessary to prevent the wood from drying out and cracking.

Stain-resistant surfaces depend heavily on the wood species and applied finishes, with some types offering higher resistance to discoloration caused by common kitchen substances.

The natural grain of butcher block can also help conceal minor scratches, contributing to a longer-lasting appearance despite rigorous daily use. Highdurability materials like hard maple possess self-healing properties where minor cuts close naturally, preserving surface integrity without immediate intervention.

Tailored cleaning techniques are essential to maintain hygiene standards, ensuring wooden countertops remain safe in environments where food preparation space endures heavy traffic.

How Marble Slabs Perform In Busy Kitchen Remodels

Natural stone surfaces require specific care due to their porous structure, which necessitates periodic sealing to minimize staining and acid damage. Custom kitchen surfaces often feature marble for its distinctive veining patterns, although the stone’s relative softness can lead to scratches under heavy use.

Thermal conductivity properties enable marble to withstand heat better than some materials; however, repeated contact with hot cookware may still affect its appearance over time.

Maintenance protocols typically involve gentle, non-abrasive cleaning agents designed to protect the surface’s finish.

Marble acquires a natural patina during aging, a characteristic that sets it apart from ecofriendly options like recycled glass surfaces or engineered stones.

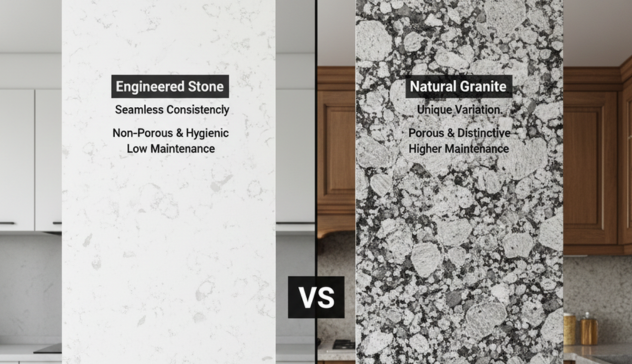

Engineered Stone Tops Versus Granite Alternatives

Composed primarily of crushed quartz combined with resin, engineered stone surfaces provide moisture-resistant materials that limit bacterial infiltration more effectively than many natural stone options. Geological variations among granite alternatives lead to differing hardness levels and thermal resistance, which can influence undermount sink compatibility during installation.

Stone composite counters exhibit a consistent texture and pattern, facilitating longer-lasting durability and simplifying refinishing tasks without requiring professional intervention.

Antibacterial finishes frequently incorporated into engineered surfaces contribute to improved hygiene, particularly beneficial in kitchens with heavy daily use.

Pricing for granite depends on its rarity and quarry source, resulting in fluctuations, whereas engineered stone maintains more stable costs despite its energy-intensive production methods.

Laminate Counters: Cost And Maintenance Tips

Homeowners often select affordable surfaces for kitchen counters to balance budget and style, with options offering diverse thickness variations that impact durability and appearance. Pricing varies considerably based on edge profiles and patterns, as some are engineered to mimic the look of granite or quartz closely.

Daily upkeep includes avoiding prolonged heat exposure to prevent warping, while stains generally do not penetrate the surface easily due to the protective wear layer.

Maintenance is simplified by routine cleaning using mild, non-abrasive detergents, which helps preserve the surface's finish and longevity.

Resurfacing techniques for these materials are limited; noticeable damage typically necessitates full panel replacement rather than repair. Usage of cutting boards and trivets is recommended to guard against scratches and burns that occur from direct contact.

Kitchen workspace optimization becomes achievable through design versatility, allowing seamless integration into various decorative themes without escalating costs. Sealing methods are generally unnecessary; however, occasional application of specialized conditioners can restore gloss and enhance protective qualities, supporting prolonged surface resilience.

Concrete Countertops For Modern Aesthetic Kitchens

Concrete is a favored material for kitchen surfaces due to its exceptional durability and ability to support high use surfaces in demanding culinary settings. Its mixture of cement blended with carefully selected aggregates and chemical additives offers diverse texture options and significantly enhances structural strength.

Unique curing techniques not only boost stain resistance but also stabilize color trends, ensuring the surface maintains its aesthetic appeal over time.

Contemporary designs emerge through the inclusion of embedded elements such as glass shards or metal flakes, creating visual effects unattainable with traditional stone slabs.

The installation process requires precise coordination because curing times and the substantial weight influence scheduling and kitchen use. Regular resealing is necessary to maintain protection against heat marks and scratching, preserving both function and appearance.

Compared to rustic countertops and premium natural stones, such surfaces provide a cost-effective alternative without sacrificing style or performance.

- Concrete countertops are highly durable and suitable for high-use kitchen surfaces.

- Special curing techniques improve stain resistance and color stability over time.

- Embedded elements like glass shards or metal flakes create unique visual effects.

- Regular resealing is required to protect against heat marks and scratches.

Soapstone Surfaces: Heatproof And Scratchproof Options

Natural stone materials exhibit remarkable resistance to high temperatures, making them a preferred choice for kitchens requiring dishwashersafe surfaces.

Their dense, non-porous structure effectively limits staining and chemical damage, minimizing the need for ongoing care tips.

Unlike many other surfaces, this stone uniquely develops a rich patina through use, enhancing cabinetry integration by blending seamlessly with evolving kitchen designs.

Minor abrasions on such materials tend to be superficial and can be restored through gentle sanding or oiling, supporting practical applications in commercial countertops.

Exceptional thermal stability helps prevent cracking during rapid temperature changes, contributing to durability and consistent kitchen performance.

Sealing Methods And Surface Hygiene For Granite Counters

The mineral composition of natural stone influences porosity, which directly affects maintenance routines and sealing intervals for durable surfaces. Longevity of counters depends largely on selecting appropriate sealants, such as penetrating sealers that infiltrate microfissures or topical sealers forming surface barriers.

Penetrating sealers provide protection beneath the surface, enhancing resistance to moisture intrusion, while topical varieties may wear faster when exposed to commercial grade materials or repair kits used during cleaning or surface restoration.

Maintaining surface hygiene requires avoiding acidic or abrasive cleaners, as these can accelerate degradation of protective layers and diminish the finish’s durability.

PH-neutral cleaning agents preserve the natural appearance without compromising sealant performance. Immediate removal of spills is recommended to prevent staining from penetrating the granite’s microstructure.

Adjusting sealing frequency and cleaning methods based on granite’s color and texture optimizes preservation, especially for heatproof surfaces with honed or polished finishes. Installation tools designed for stone surfaces ensure even application of sealants, promoting a more uniform protective coating and enhancing overall surface integrity.

- The mineral composition of natural stone affects its porosity, which in turn influences maintenance routines and sealing intervals.

- Penetrating sealers protect beneath the surface by infiltrating microfissures, enhancing resistance to moisture intrusion.

- Using pH-neutral cleaning agents helps preserve the natural appearance and effectiveness of sealants without damaging protective layers.

- Adjusting sealing frequency and cleaning methods based on the granite’s color and texture optimizes surface preservation and durability.

Ply Wood Cabinets And Cabinetry Integration Ideas

Durability testing confirms plywood’s exceptional ability to resist warping even under varying humidity levels, which is a significant advantage for kitchen environments. Ergonomic surfaces can be seamlessly integrated with plywood cabinetry due to the material’s layered construction, allowing precise joinery that supports both functionality and modern aesthetics.

Renovation materials such as plywood facilitate the creation of hidden storage compartments, maximizing available space while maintaining a favorable material cost comparison.

Unique modular cabinetry designs provide flexible reconfiguration options, accommodating evolving kitchen needs without compromising structural integrity.

Finishing techniques designed specifically for plywood enhance wear resistance and protect surfaces, ensuring cabinetry maintains both visual appeal and performance in high-traffic areas.

Kitchen Workspace Optimization With Durable Materials

Quartz and solid surface materials provide exceptional advantages for maintaining cleaner kitchen environments, offering enhanced mold resistance that inhibits microbial growth in areas prone to moisture.

Resistance to acids found in common culinary ingredients helps preserve the structural integrity of these surfaces, reducing the need for frequent surface refinishing.

UV resistance in selected countertop compositions prevents fading and discoloration, ensuring long-lasting visual appeal despite regular exposure to natural light.

Non-porous qualities improve surface hygiene by limiting bacterial penetration, which is vital for food safety in preparation zones.

Considerations of environmental impact encourage choosing recyclable and low-emission options that combine durability with ecological responsibility for sustainable kitchen designs.

Quartz and Solid Surface Materials

- Quartz countertops are engineered to be non-porous, which significantly reduces bacterial growth and enhances kitchen hygiene.

- These materials exhibit high resistance to acids commonly found in foods such as lemon juice and vinegar, preventing surface damage.

- Selected solid surface materials contain UV inhibitors that help maintain color and prevent fading when exposed to sunlight.

- Many quartz and solid surface options are recyclable and produced with low emissions, supporting environmentally sustainable kitchen designs.

At Express Kitchens, we help homeowners choose the right countertop materials and cabinetry combinations that stand up to real, everyday use. From high-traffic granite and durable quartz to low-maintenance laminate and modern concrete surfaces, our team guides customers toward options that balance strength, style, and long-term value. We also specialize in plywood cabinetry built for stability, moisture resistance, and seamless integration with today’s most popular countertop materials. Whether you’re upgrading to butcher block for warmth, selecting engineered stone for hygiene, or adding soapstone for heat resistance, Express Kitchens provides expert recommendations and professional installation to ensure your kitchen performs beautifully for years.

Frequently Asked Questions (FAQ'S)

1. Which countertop material is the most durable for high-traffic kitchens?

Quartz and granite are among the most durable choices because they resist scratches, stains, and heat better than most other materials.

2. Are butcher block countertops good for everyday cooking?

Yes, butcher block is excellent for food prep and adds warmth, but it does require regular oiling and maintenance to prevent drying and cracking.

3. Do marble countertops hold up well in busy kitchens?

Marble is beautiful but softer and more porous than granite or quartz, so it may scratch or stain more easily and needs periodic sealing.

4. Is laminate still a good budget-friendly option?

Absolutely. Modern laminate counters are inexpensive, low-maintenance, available in many styles, and can mimic the look of stone at a lower cost.

5. How often should granite countertops be sealed?

Most granite tops need sealing every 1–3 years depending on the stone’s porosity, usage level, and type of sealant applied.